INTRODUCTION

GTD Butterfly Valves are the ideal solution for the interception of gravity-fed or pneumatically conveyed dry powders or granules in a variety of bulk solids handling and processing plants.

TECHNICAL SPECS

Description

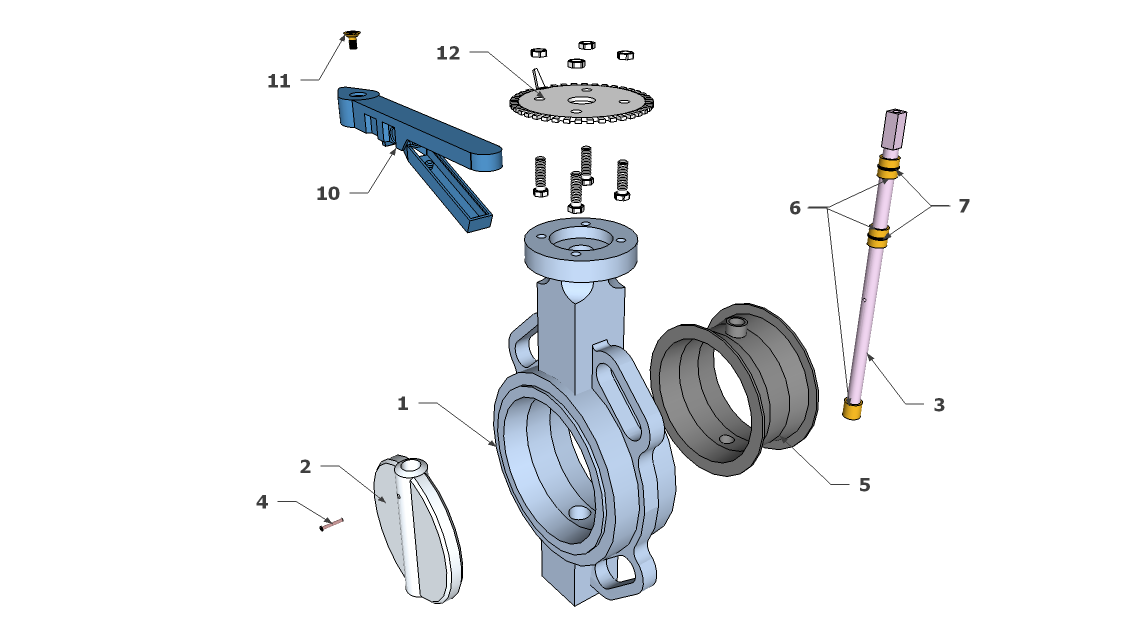

GTD Butterfly Valves consist of a single block body manufactured from die-cast , a carbon steel or stainless steel disc including shafts, and an elastomer seal. An adjusting lever or pneumatic or electric actuator can be applied to the valve. The three type actuators are perfectly interchangeable. Interchangeability of the drive shaft (standard: ISO 5211; option:DIN 5482) and universal connection to different size flanges results in variety of configurations.

Function

GTD Butterfly Valves are used in virtually all types of bulk solids processing plants where interception of gravity-fed or pneumatically conveyed dry powders or granules is required. This type of valve is particularly suitable for pneumatic conveying operations, in both dilute and dense phase applications, provided the operating pressure does not exceed 10 bar (145PSI). Due to its particular design features and the materials used, the VW Butterfly Valve represents the ideal solution in many cases, both from a technical and an economic point of view.

Features

Ø = DIN 100 ~ DIN 400

Gauge: EN 558 Series 20; ISO 5752; API 609

Coupling flanges: DIN 2501 PN 2.5 / 6 / 10 / 16; ANSI B 16.5, class 150

Coupling flange surface design: DIN 2526, form A

Actuator coupling flange: EN ISO 5211 or DIN 5482

Valve identification: DIN EN 19

Leak test: EN 12 266-1, EN 12 266-2, A grade

Operating temperature: -20 °C ~ 90 °C (-4 °F ~ 194 °F)

Differential pressure: max. 10 bar (145PSI)

Operating pressure: max.10 bar (145PSI))

Benefits

Few components

Interchangeable discs

Replaceable gasket

Highly abrasion-resistant

Easy to fit

Quick maintenance

Ex-stock delivery

Model | Size (mm) | Actuator | Media Pressure | Media Temperature |

GTD6--50-DA | 50 | DA50 | Vacuum to 10 BAR | -10°C to 100°C |

GTD6--65-DA | 65 | DA65 | Vacuum to 10 BAR | -10°C to 100°C |

GTD6--80-DA | 80 | DA75 | Vacuum to 10 BAR | -10°C to 100°C |

GTD6--100-DA | 100 | DA85 | Vacuum to 10 BAR | -10°C to 100°C |

GTD6--125-DA | 125 | DA92 | Vacuum to 10 BAR | -10°C to 100°C |

GTD6--150-DA | 150 | DA110 | Vacuum to 10 BAR | -10°C to 100°C |

GTD6--200-DA | 200 | DA125 | Vacuum to 10 BAR | -10°C to 100°C |

GTD6--250-DA | 250 | DA140 | Vacuum to 10 BAR | -10°C to 100°C |

GTD6--300-DA | 300 | DA160 | Vacuum to 10 BAR | -10°C to 100°C |

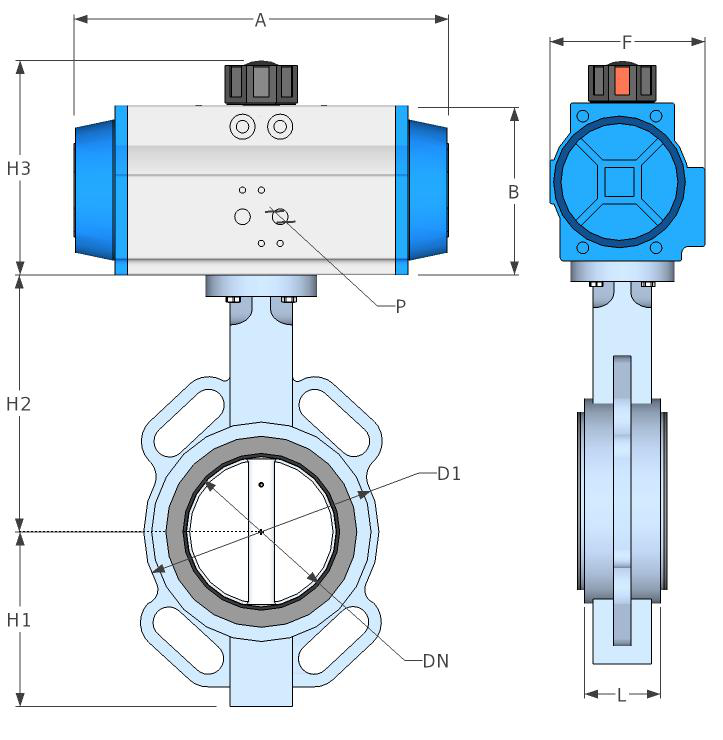

DN | Actuator | A | B | F | H1 |

50 | DA50 | 138 | 70 | 71 | 71.3 |

65 | DA65 | 138 | 70 | 71 | 77.5 |

80 | DA75 | 162 | 81 | 80.4 | 89.2 |

100 | DA85 | 162 | 81 | 80.4 | 101.5 |

125 | DA92 | 208 | 97 | 94.5 | 117.5 |

150 | DA110 | 245 | 116 | 109 | 145 |

200 | DA125 | 310 | 142 | 137 | 163.5 |

250 | DA140 | 340 | 154 | 148 | 190.5 |

300 | DA160 | 401 | 179 | 168.5 | 230 |

All dimensions in mm unless shown otherwise.

Number | Item | Material |

1 | Body | Fusion Bonded Epoxy Cast Iron |

2 | Disc | 304 Stainless Steel or cast iron |

3 | Shaft | 416 Stainless Steel |

4 | Pin | 304 Stainless Steel |

5 | Seat | Phenolic backed cartridge style EPDM |

6 | Bushings | PTFE |

7 | Stem Orings | EPDM |

10 | Visual Indicator | Thermoplastic |

11 | End Stops | 316 Stainless Steel |

12 | Actuator Ports | Anodized Aluminium |

Size 50mm to 300mm

Body FBE coated Cast Iron

Seat EPDM

Disc 304 Stainless Steel

Pressure 10 BAR

Actuation Double Acting Pneumatic