描述

不锈钢法兰球阀,用于水,空气,油和其他兼容介质的开关控制。弹簧复位执行器需要一个气动先导信号来改变阀的位置,弹簧会将阀返回到正常的故障安全位置。双作用执行器使用气压打开阀门,并使用气压关闭阀门。气动球阀相对于其他类型阀的优势可能包括:更高的流速,更高的压力,更高的温度,更广泛的介质兼容性,直通的流路,减少的水锤以及在危险环境中的使用。

技术指标

用料

主体:碳钢或不锈钢

座位:TFM或50/50

终端连接

ANSI 150#(1/2到8英寸)

ANSI 300#(1/2英寸至8英寸)

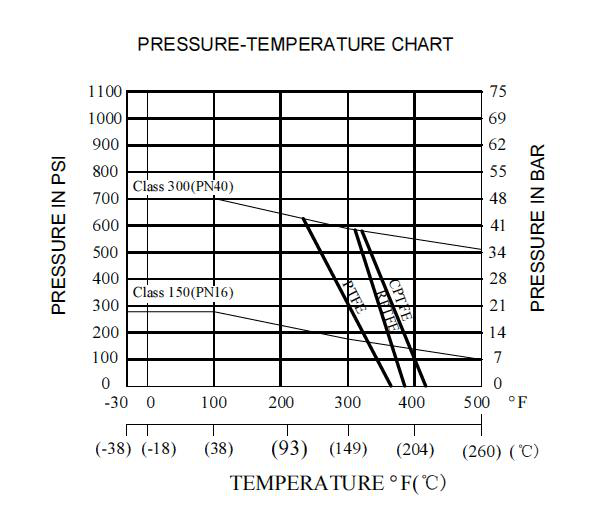

温度范围:

熔点:475°F

50/50:525°F

最大压力:

最大压差为275 PSI,WCB-285 PSI。

静水压测试(车身)和气压测试(座椅)达到以下要求:

ANSI 150#:

不锈钢:425 PSIG

碳钢:450 PSIG

ANSI 300#:

不锈钢:1100 PSIG

碳钢:1,125 PSIG

标准蒸汽工作压力:

150 SWP

可选300 PSIG

可用的执行器

防风雨电气

防爆电气

气动(单动和双动)

4-20 mA或3-15 psi气动定位器

手动杆

带限位开关的手动杆

典型应用

炼油厂

石化

化学工艺设备

过程控制应用

水和废物应用

管道应用

Model | Size (mm) | Actuator | Media Pressure | Media Temperature | Actuator Pressure |

Q641F-16C/P-15 | 15 | DA50 | Vacuum to 20 BAR (10 BAR Steam) | -20°C to 180°C | 6 to 8 BAR |

Q641F-16C/P-20 | 20 | DA50 | Vacuum to 20 BAR (10 BAR Steam) | -20°C to 180°C | 6 to 8 BAR |

Q641F-16C/P-25 | 25 | DA50 | Vacuum to 20 BAR (10 BAR Steam) | -20°C to 180°C | 6 to 8 BAR |

Q641F-16C/P-32 | 32 | DA63 | Vacuum to 20 BAR (10 BAR Steam) | -20°C to 180°C | 6 to 8 BAR |

Q641F-16C/P-40 | 40 | DA63 | Vacuum to 20 BAR (10 BAR Steam) | -20°C to 180°C | 6 to 8 BAR |

Q641F-16C/P-50 | 50 | DA75 | Vacuum to 20 BAR (10 BAR Steam) | -20°C to 180°C | 6 to 8 BAR |

Q641F-16C/P-65 | 63 | DA88 | Vacuum to 20 BAR (10 BAR Steam) | -20°C to 180°C | 6 to 8 BAR |

Q641F-16C/P-80 | 80 | DA100 | Vacuum to 20 BAR (10 BAR Steam) | -20°C to 180°C | 6 to 8 BAR |

Q641F-16C/P-100 | 100 | DA115 | Vacuum to 20 BAR (10 BAR Steam) | -20°C to 180°C | 6 to 8 BAR |

Q641F-16C/P-125 | 125 | DA145 | Vacuum to 20 BAR (10 BAR Steam) | -20°C to 180°C | 6 to 8 BAR |

Q641F-16C/P-150 | 150 | DA160 | Vacuum to 20 BAR (10 BAR Steam) | -20°C to 180°C | 6 to 8 BAR |

Q641F-16C/P-200 | 200 | DA180 | Vacuum to 20 BAR (10 BAR Steam) | -20°C to 180°C | 6 to 8 BAR |

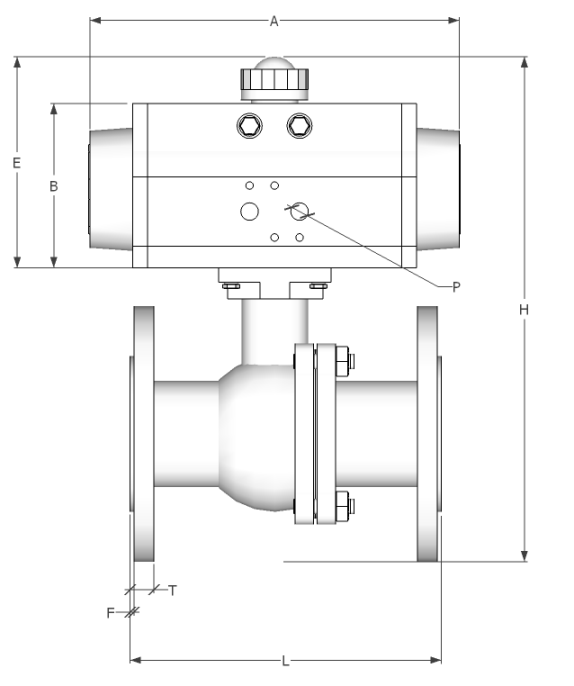

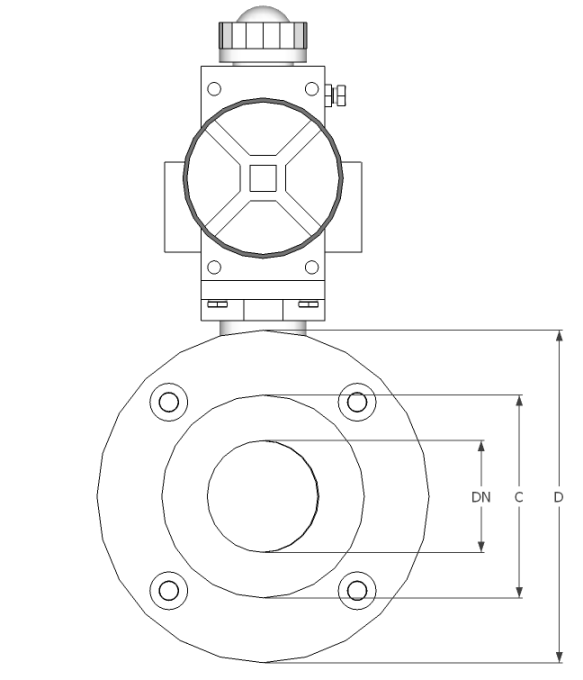

DIMENSIONS

DN (mm) | A | B | C | D | E | F | H | L | T | Actuator | P |

15 | 139 | 69 | 60.5 | 89 | 89 | 1.6 | 185 | 108 | 11.2 | DA50 | 1/8” |

20 | 139 | 69 | 70 | 98 | 89 | 1.6 | 197 | 117 | 11.2 | DA50 | 1/8” |

25 | 139 | 69 | 79.5 | 108 | 89 | 1.6 | 207 | 127 | 12 | DA50 | 1/8” |

32 | 162 | 80 | 89 | 117 | 100 | 1.6 | 244 | 140 | 12.7 | DA63 | 1/8” |

40 | 162 | 80 | 98.5 | 127 | 100 | 1.6 | 264 | 165 | 14.3 | DA63 | 1/8” |

50 | 207 | 97 | 120.5 | 152 | 117 | 1.6 | 289 | 178 | 15.9 | DA75 | 1/8” |

65 | 237 | 108 | 139.5 | 178 | 128 | 1.6 | 328 | 190 | 17.5 | DA88 | 1/8” |

80 | 271 | 121 | 152.5 | 190.5 | 141 | 1.6 | 363 | 203 | 19.1 | DA100 | 1/4" |

100 | 328 | 141 | 190.5 | 229 | 171 | 1.6 | 447 | 229 | 22 | DA115 | 1/4" |

125 | 428 | 176 | 216 | 254 | 206 | 1.6 | 565 | 356 | 23.9 | DA140 | 1/4" |

150 | 430 | 192 | 241.5 | 279 | 222 | 1.6 | 623.5 | 394 | 25.4 | DA160 | 1/4" |

200 | 482 | 222 | 298.5 | 343 | 252 | 1.6 | 728.5 | 457 | 28.6 | DA180 | 1/4" |

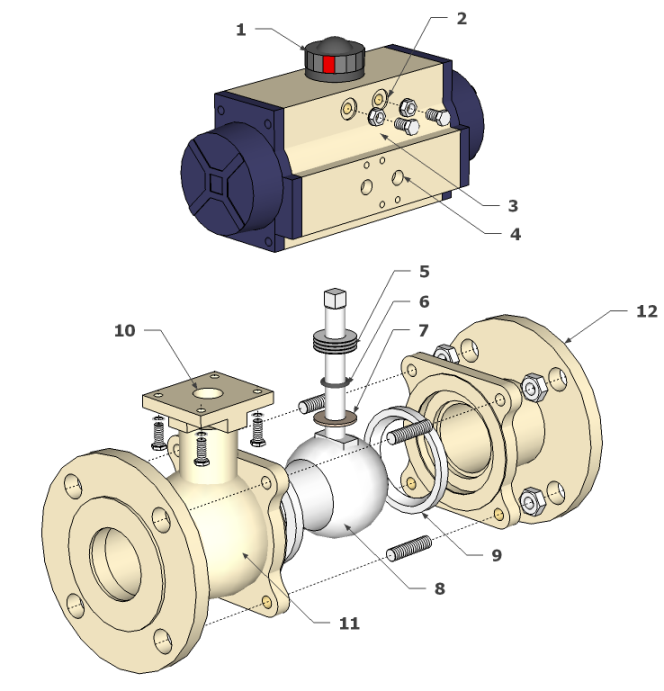

CONSTRUCTION

Item | Article | Material |

1 | Visual Indicator | UV Stabilised Thermoplastic |

2 | Adjustable Stops | 316 Stainless Steel |

3 | Spring Return Pneumatic Actuator | Sealed Aluminium |

4 | Pressure Ports / Namur Interface | Sealed Aluminium |

5 | Chevron Seals | Carbon Reinforced Teflon |

6 | Backing O-ring | Viton |

7 | Thrust Washer | Carbon Reinforced Teflon |

8 | Ball | Polished 316 Stainless Steel |

9 | Seats | Carbon Reinforced Teflon |

10 | Mounting Pad | Cast Steel & Stainless Steel |

11 | Body | Cast Steel & Stainless Steel |

12 | Flange | Cast Steel & Stainless Steel |

Size 15mm to 200mm

Body Carbon Steel & Stainless Steel

Seat Reinforced Carbon PTFE

Pressure 150 pound

Temperature -20°C to 180°C

Actuation Spring Return Pneumatic